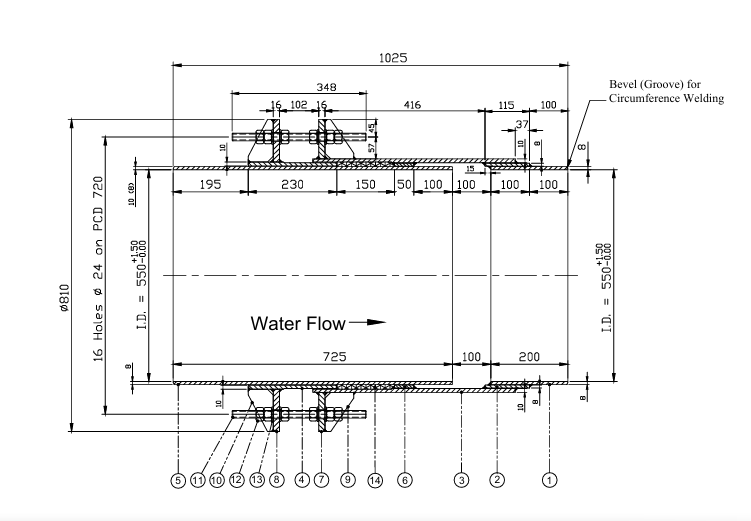

Welding expansion joints, welding compensators, is a compensation device for thermal fluid pipelines,

mainly used for axial thermal expansion displacement absorption compensation after the auxiliary installation of straight pipelines.

It is suitable for hot water, steam, grease media, and can compensate for thermal expansion through the sliding

motion of the sliding sleeve to the outer sleeve.

It is suitable for medium engineering pressure≤ 2.5MPa, medium temperature -40°C~600°C.

Expansion joint expander adopts a new type of sealing material flexible graphite ring, which has the characteristics of high strength,

small friction coefficient (0.04~0.10), no aging, good effect and convenient maintenance.

The service life of the product is large, and the fatigue life is comparable to that of the pipeline. The sliding surface is specially treated,

and has good corrosion resistance in salt water, salt solution and other environments, which is more than 50 times higher than austenitic

stainless steel. At the same time, when the sealing effect is weakened due to wear and tear after many years, the flange can be tightened

again to enhance the sealing performance, or the bolt can be loosened, the pressure ring can be removed, and then one or two layers of

sealing rings are installed, and the pressure ring can be pressed and continued to be used.

The compensator does not require chloride ion content, and is especially suitable for systems where chloride ions exceed the

standard in the medium or surrounding environment.

The compensator is divided into one-way type and two-way type compensation structure, and the two-way type is characterized

by the fact that no matter where the medium flows from the end of the compensator, the sliding sleeves at both ends of the compensator

always slide freely to achieve two-way compensation and increase the amount of compensation.